Complex Parts and Assemblies

Reverse Engineering

Are you using a critical plastic part, component, or assembly that you would like to cost reduce, improve the performance, or second source but don’t have a drawing? Semplastics’ engineering department specializes in reverse engineering complex parts and assemblies. In fact, we have built our reputation and product portfolio one part at a time by leveraging our QC and inspection expertise to measure parts and generate accurate solid models and CAD drawings.

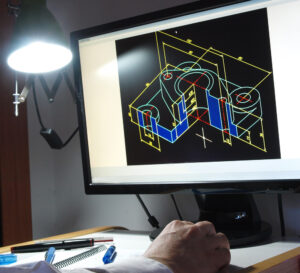

Semplastics has developed a proven methodology for reverse engineering parts that eliminates errors to insure that parts fit and perform correctly the first time. Part dimensions may need to be adjusted more than once depending on complexity. However, every effort is made to insure success by utilizing modern CAD software that can generate solid models and assemblies in 3D space to eliminate tolerance stack-ups. We also employ calibrated inspection tools such as CNC CMM’s (Coordinate Measurement Machines) and of course the most important component in reverse engineering–experienced personnel.

Once a solid model is generated for any given part or assembly, changes can be made quickly and affordably. This capability is not always available by the OEM supplier. Contact us today to speak with one of our applications engineers to improve the performance and cost reduce any precision plastic components or assembly.